When importing products from overseas manufacturers, ensuring consistent quality without inspecting every single unit is a challenge every business faces. This is where the Acceptable Quality Limit (AQL) table becomes your most valuable quality control tool. Understanding how to read and apply AQL tables can save you thousands of dollars in defective products, customer returns, and brand reputation damage.

What Is an AQL Table?

An AQL table is a statistical sampling tool based on international standards ISO 2859 and ANSI/ASQ Z1.4 that helps determine how many product samples should be inspected from a batch and what percentage of defects is acceptable before rejecting an entire shipment. Rather than checking every item in your order, AQL sampling provides a scientifically proven method to assess overall quality with reasonable confidence.

The term “Acceptable Quality Limit” has evolved from the older “Acceptable Quality Level” to more accurately reflect that it represents a limit rather than a target quality standard. AQL defines the worst tolerable quality level that can be considered satisfactory as a process average.

How AQL Tables Work: The Two-Table System

AQL inspection uses two interconnected tables to determine sampling plans:

Table 1: Sample Size Code Letters

The first table helps you identify your sample size code letter based on two factors:

Lot Size: The total quantity of products in your shipment. If you ordered multiple product types, treat each as a separate lot.

Inspection Level: The severity of inspection required. General Level II is the standard used by 98% of importers for normal product inspections, though Levels I and III are available for less or more stringent checks respectively.

For example, if you’re importing 8,000 units at General Level II inspection, the intersection in Table 1 gives you code letter “L”.

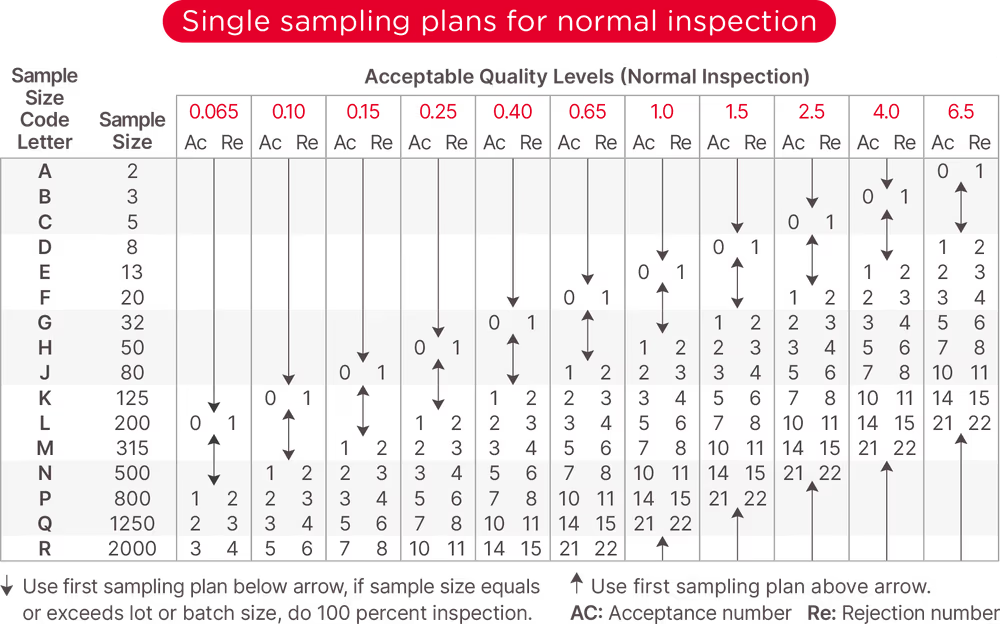

Table 2: Acceptable and Rejectable Defects

Once you have your code letter, Table 2 reveals three critical numbers:

Sample Size: How many units must be randomly selected and inspected

Acceptance Number (Ac): Maximum defects allowed to pass inspection

Rejection Number (Re): Defects that trigger batch failure

Using code letter L with AQL 2.5, you would inspect 200 randomly selected samples, and no more than 10 units may fail the inspection. Finding 11 or more defective units means the entire batch fails.

Understanding AQL Levels: When to Use 2.5 vs 4.0

The most common AQL chosen by importers is 2.5% for major defects, 4.0% for minor defects, and 0.1% for critical defects, considered the standard tolerance for most consumer products sold in supermarkets in North America and Europe.

However, it’s crucial to understand that these numbers don’t represent actual percentages of your order.

Critical Defects (AQL 0)

Critical defects are totally unacceptable issues that could lead to harm to users or violate regulations, requiring zero tolerance where any critical defect fails the inspection. Examples include:

Sharp edges on children’s toys

Chemical contamination in food contact items

Electrical hazards in electronics

Missing safety certifications

For critical defects, even finding one defective unit in your sample means automatic rejection of the entire shipment.

Major Defects (AQL 2.5)

Major defects refer to products that fail to meet quality standards during production and have a higher probability of being rejected in the market, such as a television that functions but is missing a remote control. These affect product functionality or appearance significantly enough that end customers would likely return the item.

Common major defects include:

Product doesn’t function as intended

Wrong color or significant color variation

Incorrect dimensions outside tolerance

Damaged packaging that affects product protection

Minor Defects (AQL 4.0)

Minor defects are relatively small or insignificant issues that won’t affect the product’s functionality or form, and customers won’t return the product based on the presence of one or very few minor defects. These represent cosmetic flaws that don’t impact usability.

Examples include:

Small scratches on non-visible surfaces

Slight thread loose ends on garments

Minor packaging imperfections

Color variations within acceptable tolerance

Step-by-Step: Reading AQL Tables for Your Inspection

Let’s walk through a practical example. You’ve ordered 5,000 Bluetooth speakers from a Chinese manufacturer.

Step 1: Determine your lot size (5,000 units) and select General Inspection Level II.

Step 2: Locate the intersection in Table 1. For 5,000 units at Level II, your code letter is “L”.

Step 3: Move to Table 2 and find row “L”. The sample size for code letter L is 200 pieces that must be drawn randomly from the total lot size.

Step 4: Set your AQL standards:

Critical defects: 0 (any critical defect = rejection)

Major defects: 2.5

Minor defects: 4.0

Step 5: Read the acceptance criteria from Table 2:

For AQL 2.5, the products are accepted if NO MORE than 10 products with major defects are found

For AQL 4.0, NO MORE than 14 products with minor defects are acceptable

Result: Your inspector randomly selects 200 speakers from different cartons. If they find 8 major defects and 12 minor defects, your shipment passes. If they find 15 major defects, even with only 5 minor defects, the entire batch fails inspection.

Industry-Specific AQL Recommendations

Different industries have established conventions for AQL limits based on product risk and customer expectations:

Electronics Industry: The electronics industry typically chooses AQL 1.0 and 0.65 due to higher quality expectations and functionality requirements.

Apparel and Textiles: The clothing industry generally selects AQL 2.5 and 4.0, balancing quality with the reality of manual production processes.

Medical Devices and Pharmaceuticals: Much stricter standards apply, often with AQL 0.065 or lower, especially for items where defects could cause injury.

Automotive Parts: The automotive industry commonly uses 0/1.5/2.5 AQL levels due to safety concerns and functional requirements.

Consumer Goods for Mass Retail: Standard 0/2.5/4.0 works well for products sold through mainstream retail channels.

Adjusting AQL Based on Your Market Position

Higher-end brands might want to adopt stricter standards for quality, choosing 0/1.5/4 instead of 0/2.5/4 defect levels, whereas a lower-end brand might be more tolerant of defects, opting for 0/4/6.5.

Consider these factors when setting your AQL:

Distribution Channel: Luxury boutiques require stricter standards than discount retailers.

Product Complexity: More complex products with multiple components may need tighter inspection.

Supplier Relationship: You might consider going to General I with high-performing factories or switching to General III with new or low-performing ones.

Regulatory Environment: Products sold in markets with strict consumer protection laws need lower AQL tolerance.

Customer Expectations: Premium pricing demands premium quality standards.

Common AQL Mistakes Importers Make

Mistake 1: Treating AQL as a Quality Target

AQL defines the statistical acceptance limit, not the actual target for product quality, and a lower defect rate should remain the manufacturing goal. Your supplier should always aim for zero defects, not “acceptable” defect rates.

Mistake 2: Non-Random Sampling

Samples must be randomly and representatively selected, as choosing only good-looking items compromises statistical validity. Inspectors should pull samples from different cartons, production dates, and locations.

Mistake 3: Confusing AQL Numbers with Percentages

AQL 2.5 does not mean exactly 2.5% defective allowed, as the amount of defective products is not calculated by product quantities multiplied by defective rate. The actual acceptance numbers are specified in the AQL tables.

Mistake 4: Using Inconsistent Inspection Levels

For orders with multiple product references, you should ideally perform a level II inspection on each reference at minimum, as inspecting a general level II sampling size on multiple references dilutes the sampling size and increases risks.

Mistake 5: Ignoring Critical vs Major vs Minor Classifications

Failing to clearly define defect classifications with your supplier before production leads to disputes during inspection. Document specific examples of each defect type in your quality control checklist.

Using AQL Calculators and Tools

While understanding the tables is essential, modern AQL calculators can speed up the process. Most inspection companies provide online tools where you input:

Lot size

Inspection level

AQL values for each defect type

The calculator instantly provides sample size and acceptance/rejection numbers. However, always verify results against the actual ISO 2859-1 tables to ensure accuracy.

When AQL Sampling Isn’t Enough

In certain product categories, there will be defective products in virtually every production batch, making it important to understand that AQL inspection will not guarantee a defect-free order.

Consider supplementing AQL inspection with:

First Article Inspection (FAI): Validate samples before mass production begins During Production Inspection (DUPRO): Catch issues mid-production when correction costs less 100% Inspection: For high-value items or when defect rates historically exceed AQL limits Laboratory Testing: Verify materials, safety compliance, and performance specifications

Negotiating AQL Standards with Suppliers

When establishing quality agreements with manufacturers:

Communicate Early: Include AQL requirements in purchase orders before production starts

Provide Visual References: Share photos of acceptable vs unacceptable defects

Consider Supplier Capabilities: A small company that doesn’t have much money to invest in design for manufacturing will usually set the limits at 2.5 or 1.5 for major defects and 2.5 or 4.0 for minor defects

Document Everything: Create detailed quality control specifications that reference AQL standards

Train Factory QC Teams: Ensure the supplier’s quality team understands your defect classifications

Conclusion: Making AQL Work for Your Business

The AQL table is not just a statistical tool—it’s a communication framework that aligns expectations between buyers and suppliers. The transparent AQL-based approach to sampling inspections helps you make informed decisions on whether to accept or reject an entire batch.

Start with industry-standard AQL levels (0/2.5/4.0 for most consumer goods), then adjust based on your market positioning, customer expectations, and supplier performance history. Remember that AQL represents your maximum tolerance, not your quality goal. Work with professional third-party inspection services to ensure consistent application of AQL standards across all your suppliers.

By mastering AQL tables, you gain the confidence to scale your import operations while maintaining quality standards that protect your brand and satisfy your customers.

AQL sampling does not provide a fixed confidence that the sample perfectly represents the entire lot. It provides statistical risk control: typically 95% confidence that a lot at AQL quality will be accepted, and 90% confidence that a poor lot (at the LTPD level) will be rejected.