The Rise of ESG Audits in Asian Supply Chains: From Optional to Essential

ESG audits transformed from voluntary 2020 initiatives into mandatory 2025 compliance requirements across Asian supply chains, driven by EU regulations, $30 trillion ESG funds, retailer mandates, and jurisdiction-specific frameworks in China, Japan, and Southeast Asia.

Quality Control Services in Pakistan: Essential Guide for Western Buyers

Pakistan’s $17.88 billion textile exports and specialized manufacturing in Karachi, Faisalabad, Lahore, and Sialkot require third-party quality control navigating supplier variability, infrastructure challenges, and 39% US tariffs compressing margins where defects become catastrophic.

Garment Inspections: Essential Quality Control for Apparel Importers

Garment inspections verify fabric quality, measurements, seam strength, and mandatory metal detection across critical checkpoints. Third-party inspectors provide objective verification preventing costly defects when sourcing from China, Bangladesh, Vietnam, Pakistan, or India.

The TIC Industry: Testing, Inspection, and Certification in Global Commerce

The Testing, Inspection, and Certification industry reached $263 billion in 2025, evolving from 19th-century industrial safety into sophisticated global infrastructure supporting trade compliance, ESG verification, cybersecurity, and supply chain transparency across manufacturing sectors.

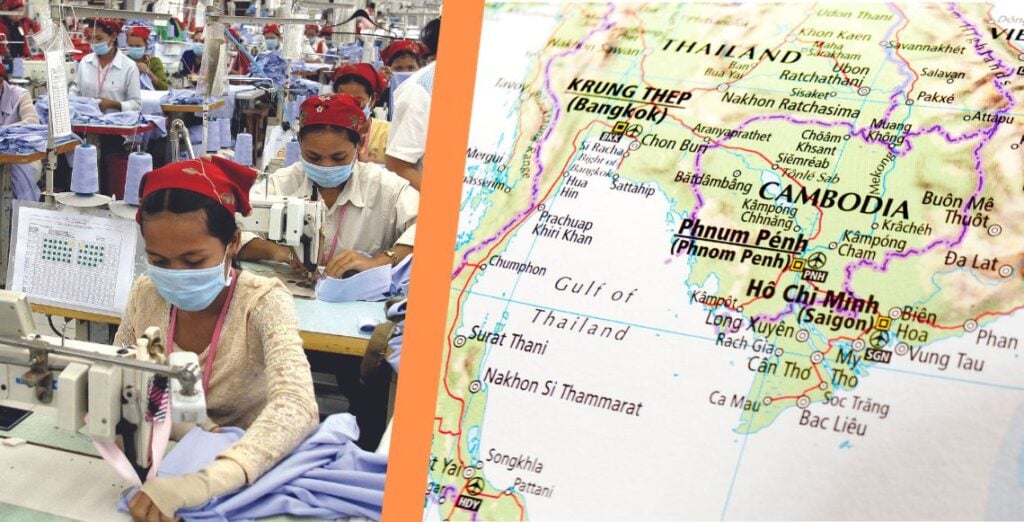

Sourcing from Cambodia: Navigating Opportunities and Tariff Challenges in 2025

Cambodia’s garment sector ($14.83B exports, +17% growth) offers competitive labor costs, but 50% Chinese factory ownership and 49% US tariff risks create substantial transshipment concerns requiring careful supplier verification and contingency planning.

Container Loading Supervision: Your Final Defense Against Shipping Disasters

A Container Loading Supervision (CLS) service verifies container condition, proper loading techniques, and accurate quantities before sealing. This final checkpoint prevents cargo damage, short shipments, and contamination that cause thousands in losses upon arrival.

Sourcing from India in 2025: Navigating the 50% Tariff Reality for US Importers

Despite 50% US tariffs on Indian imports, strategic sourcing remains viable through product optimization, supplier cost collaboration, and rigorous quality control. Inspections ($220-$350) prevent costly defects when margins compress under tariff pressure.

China’s Manufacturing Map: Where to Source by Product Category

China’s 2,000+ specialized manufacturing clusters concentrate by product category: Guangdong dominates electronics (33%), Zhejiang and Jiangsu lead textiles (38% combined), while furniture and mechanical parts distribute across multiple specialized provincial hubs.

Indonesia’s Manufacturing Emergence: The Sleeping Giant of Supply Chain Diversification

Indonesia offers 275 million consumers, abundant natural resources including 61% global nickel production, competitive labor costs, and vertical manufacturing integration for textiles, furniture, electronics, and mechanical parts despite infrastructure challenges.

Beyond Inspections: Comprehensive Quality Control Services That Transform Supply Chains

Quality control companies offer services beyond inspections including factory audits, corrective action implementation, supplier development training, process improvement consulting, and resident quality engineering that proactively prevent defects rather than reactively detect them.