[fusion_builder_container type=”flex” hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” align_content=”stretch” flex_align_items=”flex-start” flex_justify_content=”center” hundred_percent_height_center_content=”yes” equal_height_columns=”no” container_tag=”div” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” border_style=”solid” box_shadow=”no” box_shadow_blur=”0″ box_shadow_spread=”0″ gradient_start_position=”0″ gradient_end_position=”100″ gradient_type=”linear” radial_direction=”center center” linear_angle=”180″ background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ background_blend_mode=”none” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” absolute=”off” absolute_devices=”small,medium,large” sticky=”off” sticky_devices=”small-visibility,medium-visibility,large-visibility” sticky_transition_offset=”0″ scroll_offset=”0″ animation_direction=”left” animation_speed=”0.3″ filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ admin_toggled=”yes”][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”5_6″ align_self=”auto” content_layout=”column” align_content=”flex-start” valign_content=”flex-start” content_wrap=”wrap” center_content=”no” column_tag=”div” target=”_self” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” order_medium=”0″ order_small=”0″ hover_type=”none” border_style=”solid” box_shadow=”no” box_shadow_blur=”0″ box_shadow_spread=”0″ background_type=”single” gradient_start_position=”0″ gradient_end_position=”100″ gradient_type=”linear” radial_direction=”center center” linear_angle=”180″ lazy_load=”none” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ animation_direction=”left” animation_speed=”0.3″ margin_bottom=”0px” last=”true” border_position=”all” first=”true” min_height=”” link=””][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”” rule_size=”” rule_color=”” hue=”” saturation=”” lightness=”” alpha=”” content_alignment_medium=”” content_alignment_small=”” content_alignment=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” class=”” id=”” margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” fusion_font_family_text_font=”” fusion_font_variant_text_font=”” font_size=”” line_height=”” letter_spacing=”” text_transform=”” text_color=”” animation_type=”” animation_direction=”left” animation_color=”” animation_speed=”0.3″ animation_delay=”0″ animation_offset=””]

Quality control is a vital aspect of any manufacturing process, and it involves various types of inspections to ensure that products meet the required quality standards. In this article, we will explore the differences between four types of inspections: first-article inspection, in-process inspection, pre-shipment inspection, and container loading supervision.

First-article inspection

A first-article inspection is a comprehensive examination of the first production item in a manufacturing process. It is conducted to ensure that the product meets all the specifications, design requirements, and performance standards before beginning mass production. This inspection is crucial in the manufacturing process, as it helps to identify and correct any defects or issues that may arise during the production process. A first-article inspection typically involves a thorough examination of the product’s materials, design, dimensions, and performance characteristics.

In-process inspection

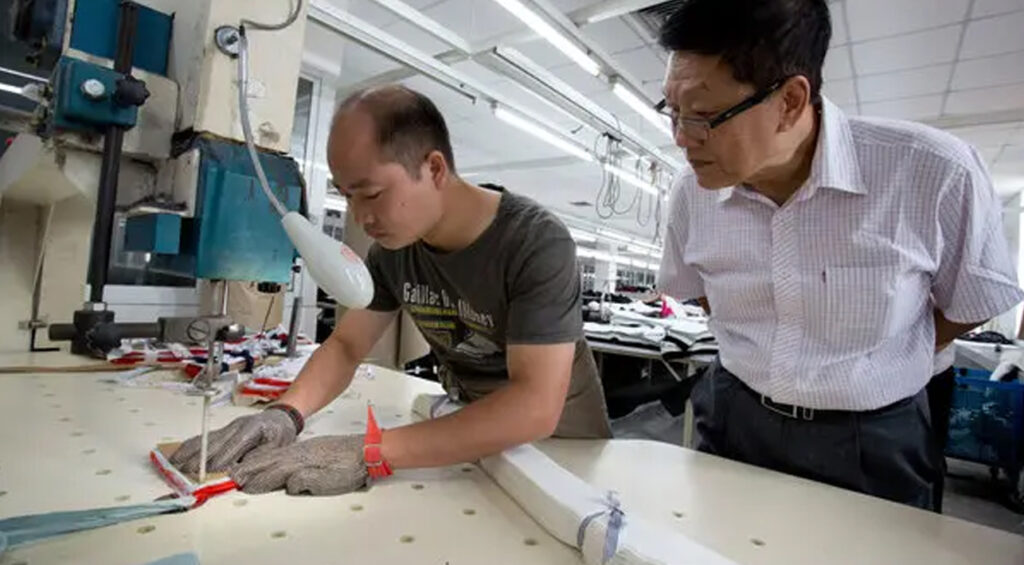

An in-process inspection is conducted during the manufacturing process and is carried out at specific stages of production to ensure that the product meets the required quality standards. This type of inspection can help to identify and correct any issues that arise during production before they become major problems. In-process inspections may involve testing the product for functionality, verifying dimensions, and ensuring that the product’s materials and components meet the required standards.

Pre-shipment inspection

A pre-shipment inspection is a final quality control check that is conducted before the products are shipped to the customer. This inspection is carried out to ensure that the product meets all the required quality standards and specifications, as agreed upon by the manufacturer and the customer. Pre-shipment inspections may involve a thorough examination of the product’s design, dimensions, materials, and performance characteristics, as well as any other specific requirements requested by the customer.

Container loading supervision

Container loading supervision is an inspection carried out at the point of loading the products into shipping containers. This inspection is conducted to ensure that the products are loaded and secured properly in the shipping containers, to prevent damage during transportation. Container loading supervision may involve verifying the quantity of products being loaded, inspecting the packaging and labeling, ensuring that the products are loaded according to the customer’s requirements, and monitoring the loading process to prevent any damage to the products.

Differences between the inspections

While these four types of inspections all have the same end goal – ensuring that the products meet the required quality standards – there are some key differences between them.

Timing: The timing of each inspection differs. The first-article inspection is conducted before the start of mass production, while in-process inspections are conducted at various stages during production. Pre-shipment inspections are conducted at the end of the production process, while container loading supervision is conducted at the point of loading the products for shipping.

Scope: The scope of each inspection also differs. First-article inspections are conducted on the first item produced, while in-process inspections are conducted on a sample of items during the production process. Pre-shipment inspections are conducted on the entire batch of products, while container loading supervision is focused solely on the loading process.

Purpose: The purpose of each inspection also varies. First-article inspections are conducted to identify and correct any defects or issues in the first item produced, while in-process inspections are carried out to ensure that the product meets quality standards during production. Pre-shipment inspections are conducted to ensure that the entire batch of products meets the required quality standards before shipment, while container loading supervision is conducted to ensure that the products are loaded properly to prevent damage during transportation.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]